The “top of the range” of Rilecart machines. Thanks to its design and its wire insertion system, the machine combines flexibility, versatility and reliability. Can punch and bind “in line” with double loop wire books, pads, exercise books, diaries and many other items.

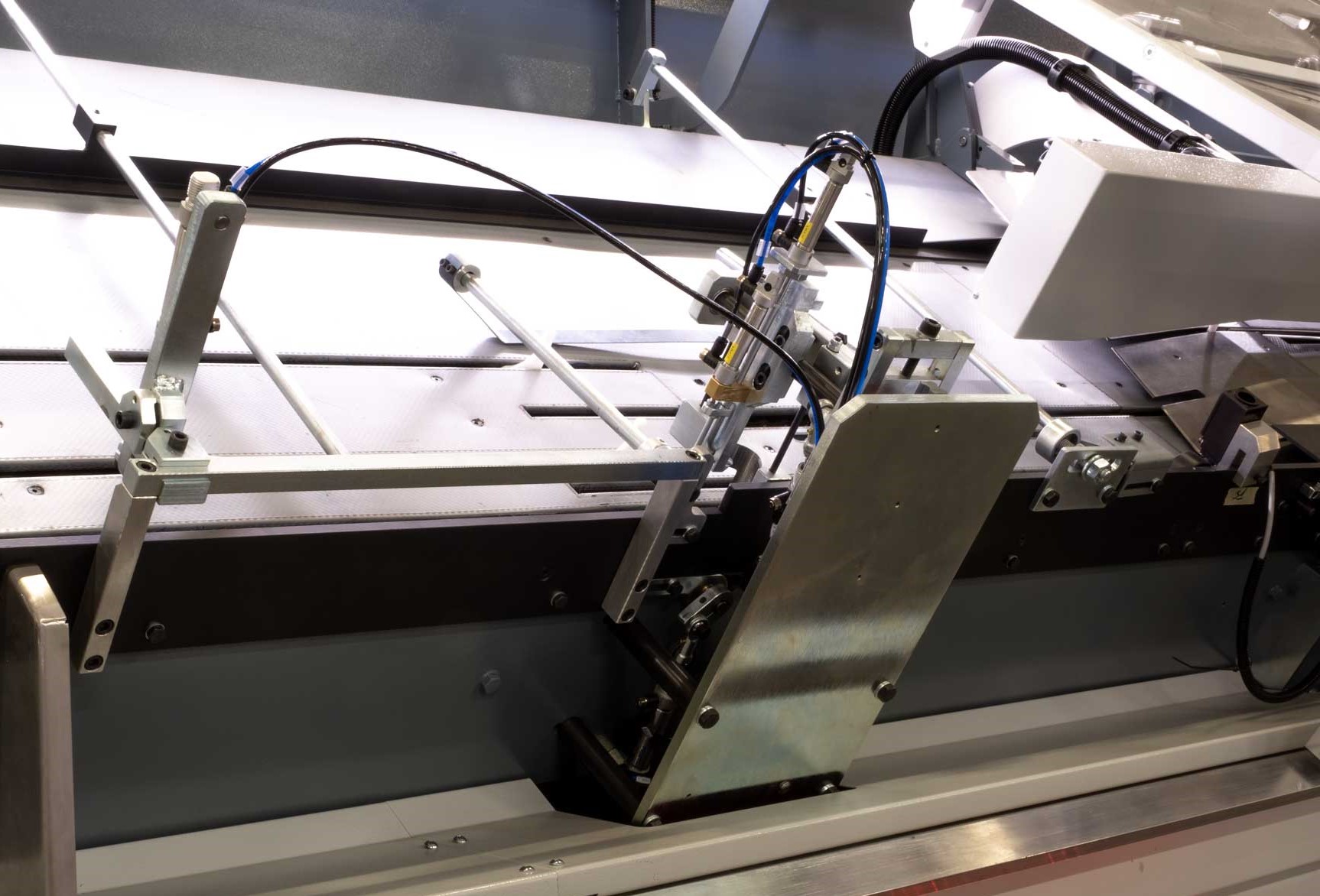

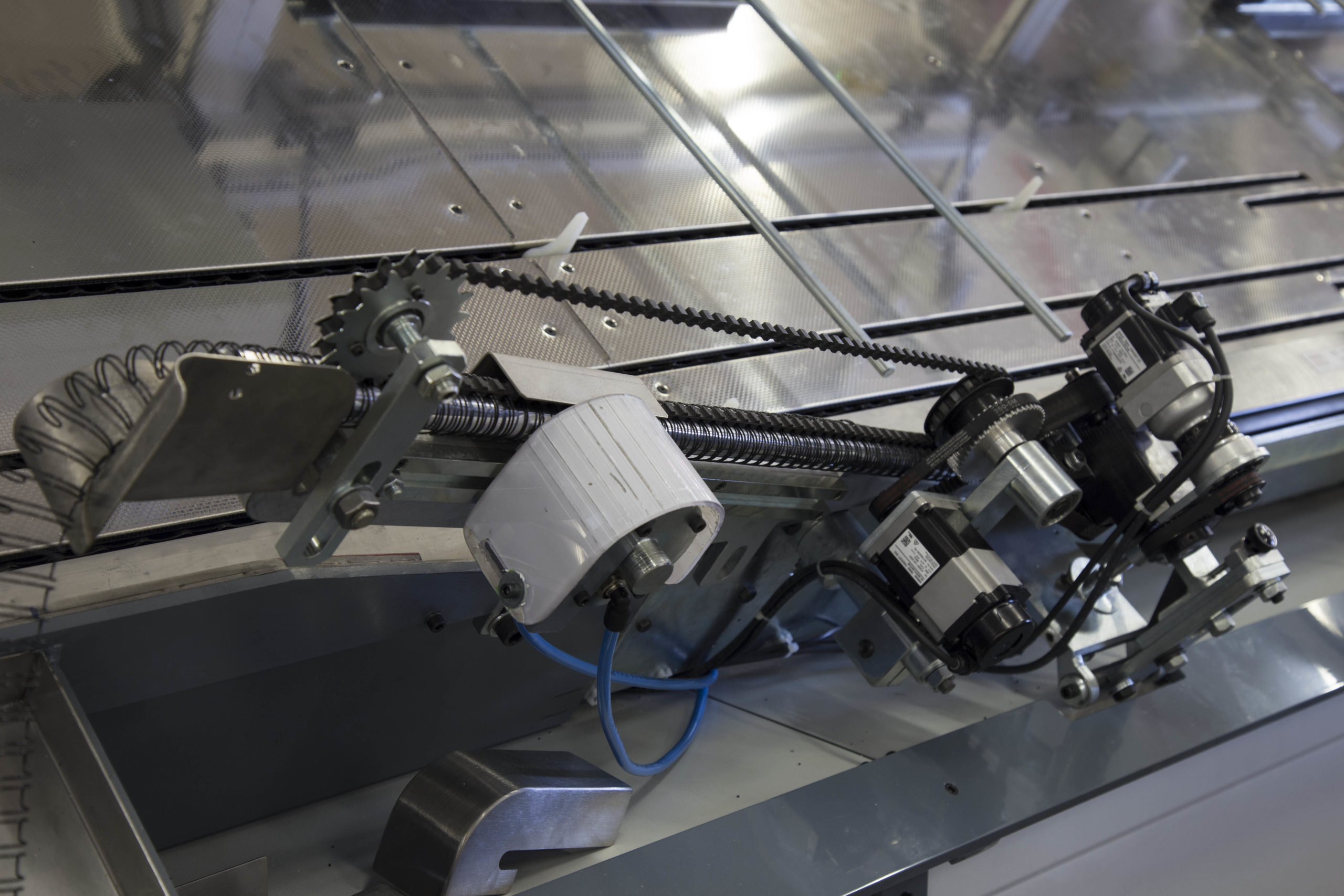

The line is composed by the automatic double-side punching machine DP-420 in line with the automatic binding machine B-599 H.F. The punching unit, using of a set of blades, divides the item in booklets of 5 mm. first , then in 2,5 mm. and punch them separately thanks to a double (superior and inferior) punching tool. The machine then gathers the booklets and brings the book to the closing unit where is automatically bound. The two machines can work together or, when required, off line.

HOW IT WORKS

The line is composed by the automatic double-side punching machine DP-420 in line with the automatic binding machine B-599 HF BF.

The punching unit, using a set of blades, divides the item in booklets of 5 mm. first , then in 2,5 mm. and punch them separately thanks to a double (superior and inferior) punching tool. The machine then gathers the booklets and brings the book to the closing unit where it is automatically bound.

The two machines can work together or, when required, off line.

FEATURES

Uses wires on spools.

For all 3:1” and 2:1” pitch from 1/4” to 1-1/4”.

Binding size: Max = 420 x 420 mm., Min = 100 x 100 mm.

Dividing thickness: Max: 5 mm., Min: 3 mm.

Punching thickness: Max: 5 mm. per stroke.

Dedicated tools for each diameter.

Max productivity: from 500 to 3000 pieces/hour according to the thickness of the product:

3-5 mm. (1 booklet) = 3000 pcs/h

5-10 mm. (2 booklets) = 1500 pcs/h

10-15 mm. (3 booklets) = 1000 pcs/h

15-20 mm. (4 booklets) = 750 pcs/h

20-25 mm (5 booklets) = 600 pcs/h

Effective speed depends on the technical features of the item and on production organization.

The speeds shown are related to paper of weight not less of 80 gr./sqm.

OPTIONALS

Size tool sets: 1/4” to 1-1/4”.

Additional punching tool.

TECHNICAL SPECIFICATIONS

400 V 3-phase 50/60 Hz + Neutral; 16Kw

8 Atm - 10mc/hour

H 9500 x D 3600 x L 2000 mm

3500 Kg