Our “Best Seller” product. Perhaps our most famous and simplest semiautomatic machine. Perfect for binding calendars and catalogues. Easy to use, easy to maintain and exeptionally sturdy. It’s particularly high precision binding with small diameters allows a perfect finish with the thinniest products. Equipped with the new touch screen control system.

Optionals:

Technical Specifications:

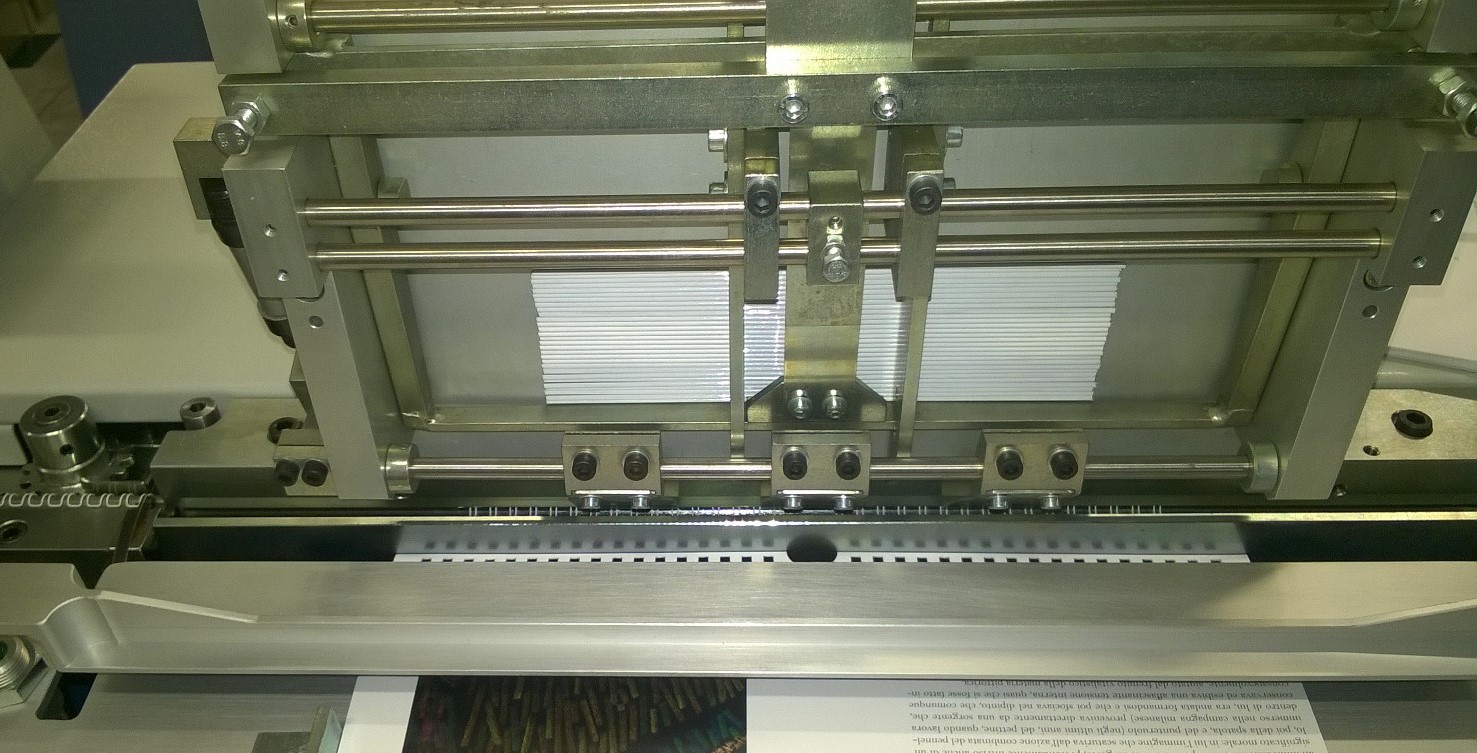

R-500 T.S. Semi Automatic binding machine

Our “Best Seller” product. Perhaps our most famous and simplest semi automatic machine. Perfect for binding calendars and catalogues.

Easy to use, easy to maintain and exceptionally sturdy. It’s particularly high precision binding with small diameters allows a perfect finish with the thinnest products. Equipped with the new touch screen control system.

HOW IT WORKS

The operator inputs in the computer diameter, pitch and wished number of loops per length. Then lay down the pre-punched product onto the worktable and press the foot pedal. The machine automatically unwinds the spool, cuts the wire and carries each length into the binding tool. The clamp on the worktable locks the product with the punched edge towards the spiral. The table forwards the product into binding position and the product is then bound by means of a closing tool that can be quickly interchanged when changing spiral diameter. During the closing operation also the hanger can be inserted. The R-500 can mount either the semi automatic 100-

300 mm. hanger distributor.

It is now available also the automatic hanger former for straight hangers, that allows to save a remarkable amount of time wasted in the hand operations of setting the hangers correctly on the semi automatic hanger feeder.

FEATURES

Uses wires on spools 3:1”, 2:1” or 4:1” pitch.

Great flexibility, 7 different wire diameters can be used from

3/16” up to 9/16” with appropriate Size-Tool-Sets.

Maximum binding length is 500 mm., minimum 50 mm.

Maximum binding thickness is 11,5 mm. of pre punched sheets.

Can bind one length of wire, or two identical for wall calendars, or up to ten for skip-binding.

Microprocessor controlled with touch screen.

The machine operates electrically and pneumatically and must be connected to a compressed air supply.

Machine speed is over 1500 cycles per hour. Effective productivity depends on operator skill and on the products’ features.

OPTIONALS

Hanger feeder for 100-300 mm. hangers.

Hanger former 100-300 mm. for straight hangers.

Remote assistamìnce module.

TECHNICAL SPECIFICATIONS

220 V single phase 50/60 Hz; 2 Kw

6 Atm – 150 It/min.

H 1400 x D 700 x L 2200 mm.

485 Kg