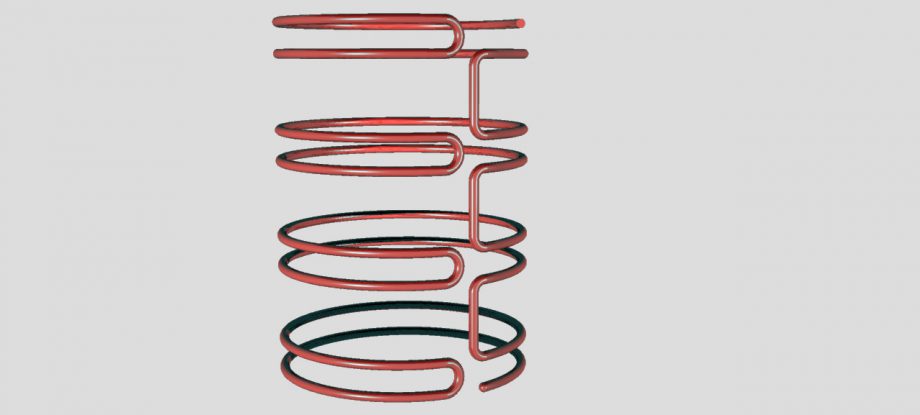

Double loop WireBind Rilematic® are manufactured by special forming machines specifically designed by Rilecart R & D department.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras sagittis quis ipsum vitae dictum. Maecenas venenatis turpis lectus, convallis suscipit lectus interdum sit amet.

Rilecart Double-loop spirals are undoubtedly the most elegant and functional binding / finishing solution for a large spectrum of products.

The Double-loop spiral is made of a particular steel alloy available in a large variety of colours. The benefits of this system over the traditional binding methods are numerous:

The pages can easily rotate over 360°, allowing maximum freedom and functionality when reading. This is particularly useful for calendars as it removes the need to tear off the page, which can be kept, thus extending the average life by years.

Exercise books and note pads can be easily used on both sides.

Manuals, guides, instruction manuals can be read with one hand only, and in any case, compared to traditional binding systems, only take up half the space.

The product can be easily laid flat (at 1800) allowing ease of consultation and preventing wearing of the side. Just think how much simpler reading a recipe book or a musical score sheet becomes.

Compared to the traditional single wire bind, the alignment is perfect and the overall robustness of the product far greater.

The double loop is an environmentally friendly and clean solution from a minimal environmental impact technology

Compared to the plastic side covers, page wear on double bind products is greatly reduced thanks to the mismatch between the profile of the page and the sharp plastic edge.

Small objects or other materials can also be included in the end product.

Variety in the end effect and functional quality is ensured by the range of binding solutions available. It is possible to encase the spiral bound material, partially reveal the spiral by using a single crease cover. The spiral can also be Skip laid, i.e. alternating holes and empty spaces.

The double ring allows the assembly if various materials: plastic and PVC, paper and cardboard, but also leather, aluminium, etc. All this in the most unusual shapes, giving a free hand to the visual department and the Product Manager.

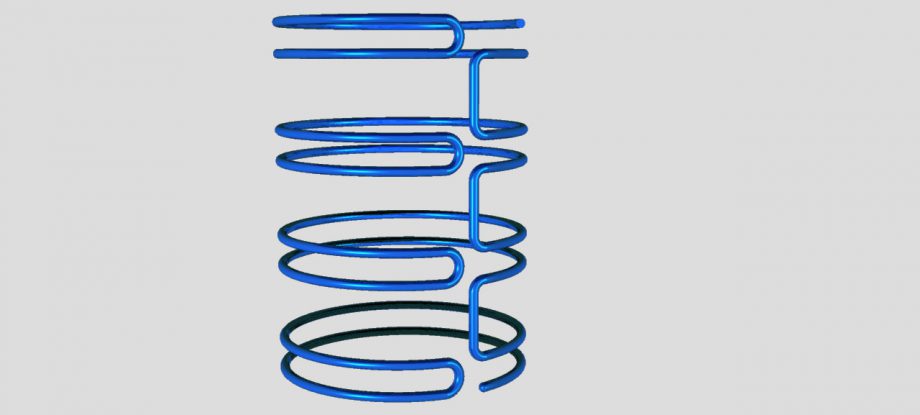

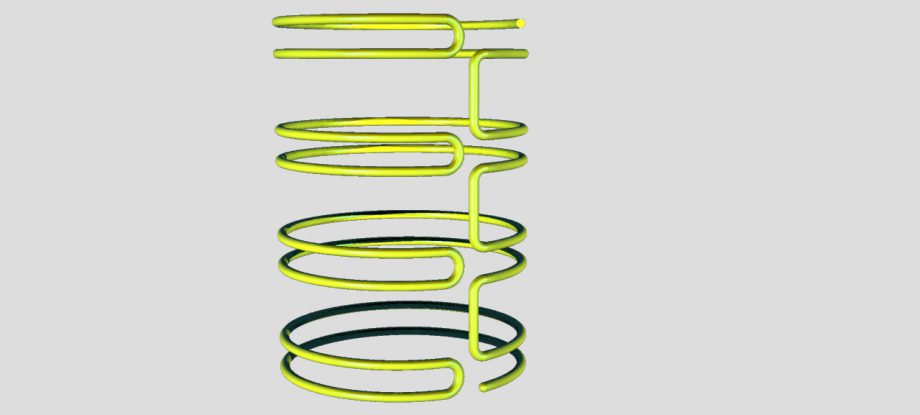

The wide selection of available colours allows combinations of great visual appeal.

Documents, catalogues, calendars will therefore be uniquely differentiated and highly functional.

In terms of productivity, this system also delivers significant benefits. The current technology is relatively simple, efficient and can be set up with minimal upfront investment, building up over time to bigger and more productive equipment.

Double-loop spirals are produced “open” to be successively inserted in pre-punched holes of the product and then closed.

The main operations in the binding process are:

Those operations can be performed in different ways, from small hand operated machines, up to big automatic or semiautomatic solutions: Rilecart is currently the company offering to the market the widest spectrum of machinery type.

Double loop WireBind Rilematic® are manufactured by special forming machines specifically designed by Rilecart R & D department.

This allows us to have an advanced know-how of the production process, with the net result of a superior quality product. This in turns means:

Our remarkable productive cycles allow us prompt delivery in the 12 different diameters and in the different available colours (for a total of 240 items!).

To ensure best quality, we use only the best material available on the market. We sell the wire in spools, in customer defined lengths and sin standard office boxes. We also manufacture hooks for calendars of any size from 6 to 50 cm in the same colours and material of the wire binds, and in 6 different models: “Little”, “Big”, “Special”, “Tall”, “Euro”, “Right”. Hooks are also available on rolls in the same lengths (from 7 to 50 cm) and in the same models.

WireBind Rilematic® Wire provides: