A further step for the automation of double loop binding. A clever and flexible machine able to punch and bind in line up to 1”. Using the best of Rilecart technology, compact and user friendly, this machine is the perfect solution when in need to replace semiautomatic machinery with no risk of an underutilized investment.

Calendars and books have to be put on the machine already collected. Then, depending on the thickness of the product the machine can be used in three ways:

The PB-735 HD DP can be connected to gathering machines.

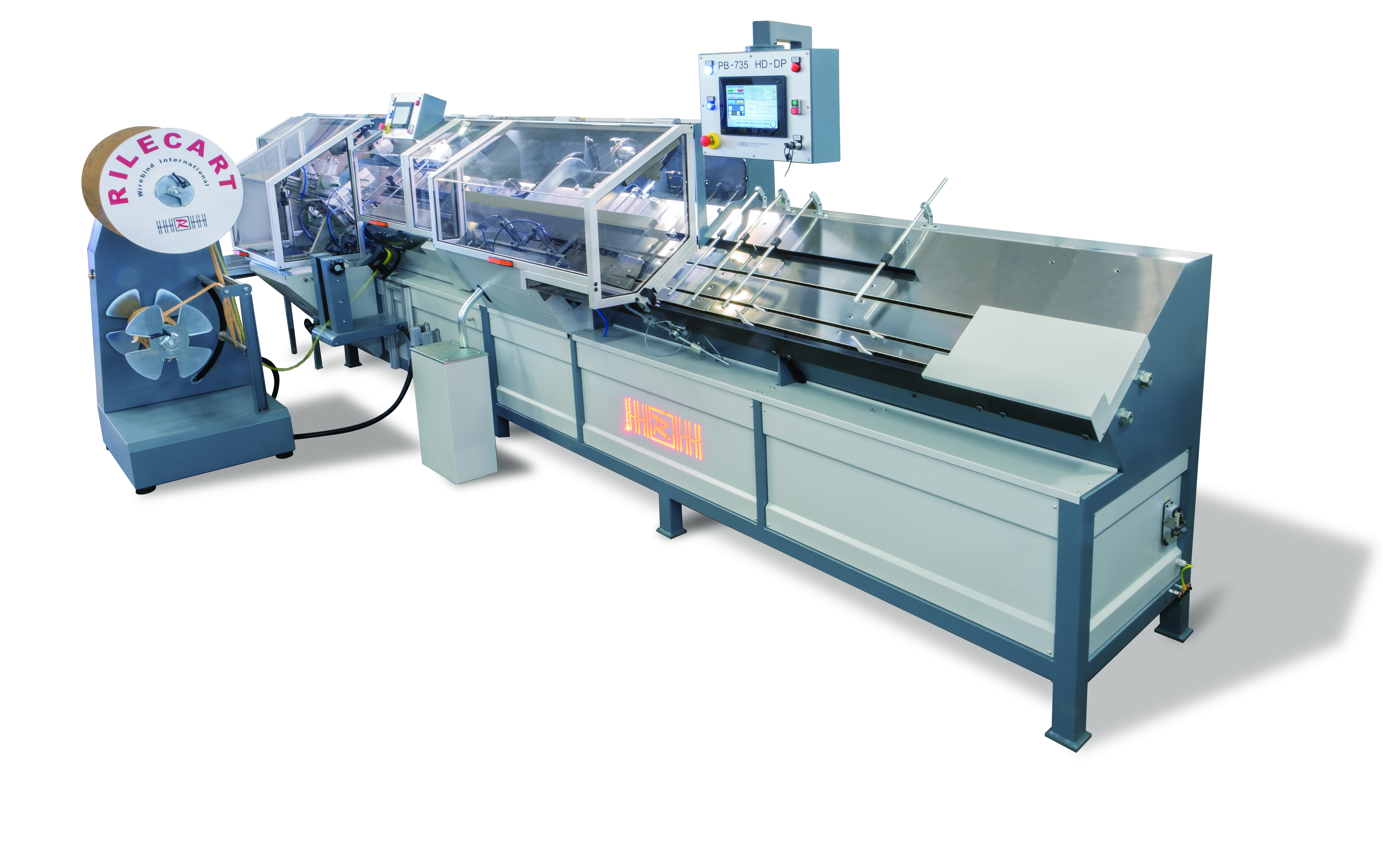

PB-735 HD DP HC Automatic punch and bind machine for books and calendars

A further step for the automation of double loop binding. A clever and flexible machine able to punch and bind in line up to 1”. Using the best of Rilecart technology, compact and user friendly, this machine is the perfect solution when in need to replace semi automatic machinery with no risk of an underutilized investment.

HOW IT WORKS

Calendars and books have to be put on the machine already collected. Then, depending on the thickness of the product the machine can be used in three ways:

1. Thickness less than 4 mm.: The machine in this case works in line without anything else to do, simply has to pick up the product bound on the conveyor.

2. Thickness from 5 mm. to 10 mm.: it is necessary to use the separating blade and split the product in two booklets that will be punched separately by the double-action punching tool.

3. Thickness more than 10 mm.. It is necessary to split the book in several parts and then it will be automatically reassembled and bound.

The PB-735 HD DP can be connected to gathering machines.

FEATURES

Uses wires on spools.

Maximum binding size:

for products up to 4 mm. thickness: 350 x 500 mm.

for products over 4 mm. thickness: 350 x 420 mm.

Minimum binding size: 100 x 100 mm.

Maximum punching thickness per stroke: 8 mm.

(4+4 mm. depending on pitch, materials and width of the product).

Standard binding diameters: 1/4” (on request 5/16”, 3/8”,

7/16”, 1/2”, 9/16”, 5/8”, 3/4”, 7/8” and 1”).

Standard pitch 3:1” (on request 4:1” or 2:1”).

Speed variable 500 to 2500 pieces/hour depending on size, thickness and quality of materials.

Can be programmed for continuous binding, two pieces with hanger or “skip-binding”.

Central automatic lubrication.

Remote assistance module.

OPTIONALS

Automatic device for hangers from 100 mm. to 200 mm.

Option for automatic hanger feeder with hanger former.

TECHNICAL SPECIFICATIONS

400 V 3-phase 50/60 Hz + Neutral; Kw 10

6 Atm – 30 mc/hour

H 1100 x D 2000 x L 4500 mm.

2100 Kg